Engine Components: The Heart of Performance

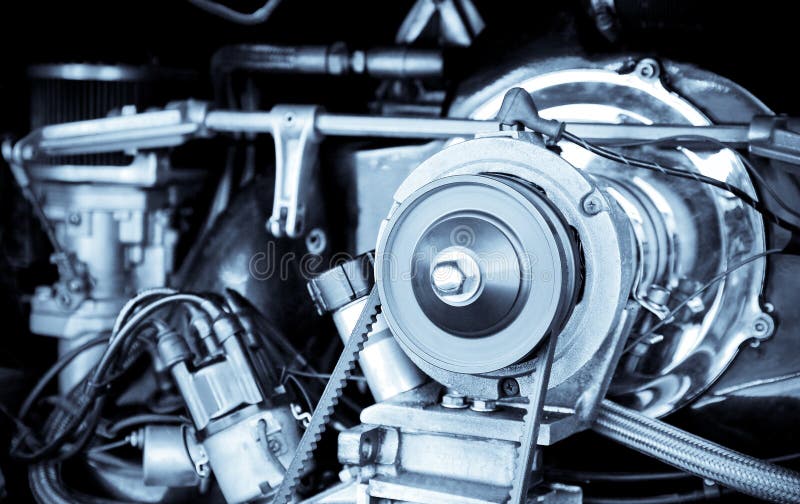

Engine parts represent some of the most critical components in any automotive or mechanical system. From pistons and connecting rods to camshafts and valve assemblies, each component must work in perfect harmony to deliver optimal performance. Modern engines operate under extreme conditions, with temperatures exceeding 2000°F and pressures that can reach several thousand PSI.

Quality engine components are manufactured using advanced metallurgy and precision machining techniques. Forged pistons, for example, offer superior strength compared to cast alternatives, while precision-ground camshafts ensure accurate valve timing. These manufacturing differences directly impact engine longevity, fuel efficiency, and power output.

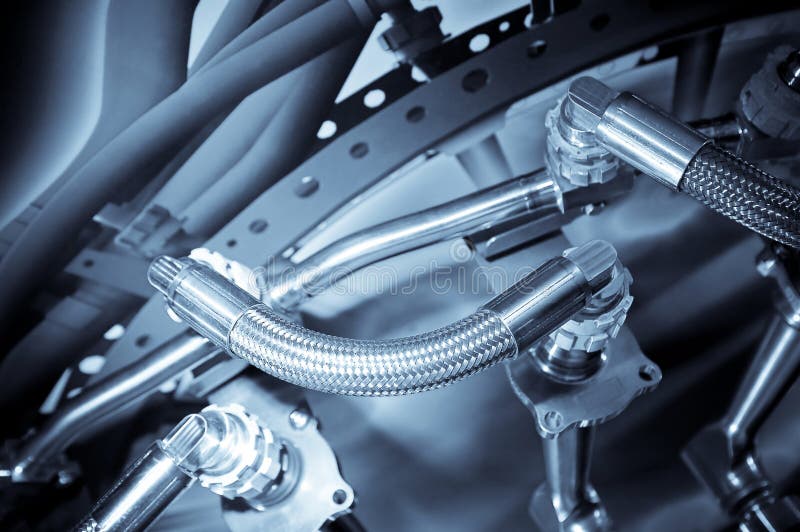

When selecting engine parts, consider factors such as material composition, manufacturing tolerances, and compatibility with your specific application. Premium components often feature advanced coatings like DLC (Diamond-Like Carbon) or specialized heat treatments that enhance wear resistance and reduce friction, contributing to improved performance and extended service life.